Français

Français

Manufacturer of Hydraulic Presses

When a hydraulic press does not reach its appropriate pressure in time or it is making odd noises, you may have some problems that would mean it is

time for a new press. Even p resses that have had regularly scheduled maintenance can experience issues from simply being used for several years or from being run with a problem operators may have been unaware of. Learning more about how to know when to replace your hydraulic press is important to avoid down time in production.

resses that have had regularly scheduled maintenance can experience issues from simply being used for several years or from being run with a problem operators may have been unaware of. Learning more about how to know when to replace your hydraulic press is important to avoid down time in production.

Pumps And Relief Valves

One of the most common problems in hydraulic presses is leaks. In some cases, leaks can be small and unnoticeable until they are bigger and causing greater problems. If your press is not reaching the correct pressure in the appropriate time, you could have a problem with the pump. If a malfunctioning pump is caught in time, a new pump can save you from needing a complete press replacement. A faulty pressure relief valve can also cause pressure problems. If there is a problem in the motor of a press, pressure can become compromised as well. Experienced press mechanics recommend shop owners learn how their press acts and sounds when it is running at optimum pressure and speed. In this way, any noises or other changes are apparent right away. The tiny problem that is not repaired in a timely manner can become the big problem that causes the purchase of a new press.

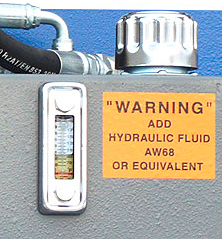

The Importance Of Clean Oil

Oil maintenance can help you avoid several major problems in press operations. Making sure oil changes are done yearly is important because oil can become dirty and cause troubling lubrication issues. Old oil can become filled with damaging particles that will interrupt the smooth running motor. Bear in mind the ram should never have oil dripping from it, but it should always remain moist for smooth operation. Regular oil checks can help prevent serious and more expensive repairs in the future.

Electrical Failure

The electrical system in a press is another important aspect of maintenance checks. Valve coils can become worn out and if not replaced, your press could experience problems that will shut down the press. Normally, valve coils last up to three million strokes. Relay switches generally last up to one million strokes. When electrical parts are operating correctly, your press receives enough motor power to produce correct pressure. When electrical systems experience problems, presses can stop or slow down, causing down time and in many cases, costly repairs. Taking the time to ensure all electrical parts on your press remain in good working condition is vital to maintaining uninterrupted production.

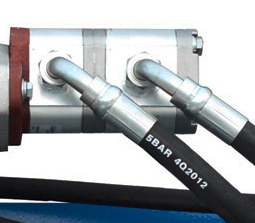

Hoses And Crimping

Hydraulic hoses must be properly maintained or your press will lose pressure. Leaking hydraulic fluid can also become a safety hazard in the workplace. Hose should be checked regularly for cracking and unusual crimping as well. Crimping issues can cause plumbing issues that will directly impact press pressure. Hoses should always be tended to by a trained professional. Correct crimping ensures hoses are able to handle the pressure used by the press they are associated with. Making sure hydraulic fluids are topped off regularly is also important for smooth operation and for your press to be able to reach the correct level of pressure.

Cracked Frames

Frame cracks can be subtle and still cause serious problems with force absorption and smooth press functioning. Fatigue cracks can start out small and continue to lengthen during continued use, causing press function to become off kilter. Welding frame cracks generally only provides a temporary fix, giving you time to make arrangements for a new press. If you are unsure about the correct welding of a crack, it is best to contact an expert. However, you might also consider the benefits of purchasing a new press from a reputable, trusted manufacturer for remaining on top of your production and ahead of the competition.

In With The New, Out With The Old

When the time comes for a press replacement, knowing it is time is crucial to prevent costly down time in production. This is another important reason to know your machine well through regular maintenance. Many machine shops and other industries depend on the parts made with hydraulic presses, an important reason it is vital to know when to replace your hydraulic press.

Contact RK Machinery to let us help you get the best hydraulic presse.